Filed under: 3D, Equipment, Lighting, On Location, photogrammetry, RTI | Tags: Maori weaving, photogrammetry, RTI, TeRa

In January 2020 Mark Mudge and I traveled to the British Museum in London to document the only existing Māori canoe sail of its kind, made over 200 years ago. The imaging work was performed in collaboration with the New Zealand project Te Rā – The Māori Sail Whakaarahia anō te rā kaihau! – Raise up again billowing sail! funded by The Royal Society – Te Apārangi Marsden Fund.

The New Zealand team produced a 13½-minute video of the project that you can watch here: Imaging Te Rā at the British Museum 2020

helps prepare the sail for imaging

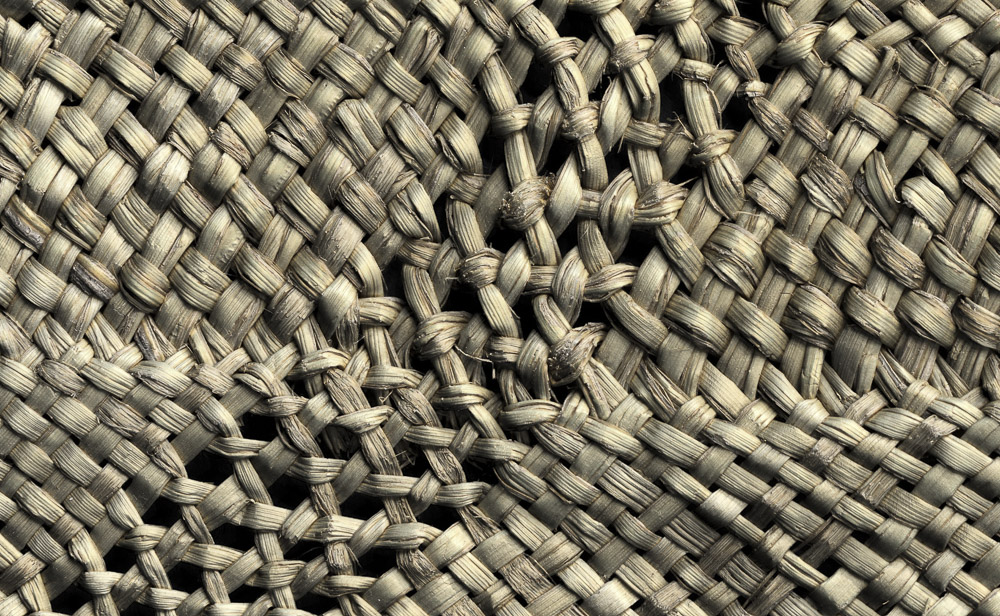

The construction and materials of the last known Māori sail, Te Rā, had not been identified, documented, or made publicly available, until this project put significant efforts into these identifications and documentation. Māori textile researchers from New Zealand brought in CHI to image the sail, which is made with fragile plant materials and feathers. The CHI team used both photogrammetry and Reflectance Transformation Imaging (RTI) to help the experts examine and understand more about the delicately woven and perishable materials. The research team wanted to gain a greater understanding of how the Māori sailed the ocean and the intricacies of their weaving techniques.

We worked with the sail on site at the British Museum for 5 days.

The first day was all preparation: meeting the team, examining the sail, setting up equipment, testing lights, and troubleshooting. The second day was spent on the imaging. The initial preparation had begun back in the CHI studio in San Francisco, when Marlin Lum, Imaging Director, prepared for the intensive imaging project by creating a life-size paper template of the sail so the CHI team could work out the imaging logistics ahead of time. Marlin had also created an ingenious camera rig to manage the imaging and protect the fragile materials. Marlin’s rig was attached to a rental pro video slider unit that we picked up in London on the first morning.

At the museum collection facility, the sail was spread out on a protective foam core platform on the floor, covered by black paper. Because the sail has a pattern of holes in it, we performed tests on how best to mask out the holes so that they would be correctly modeled as holes in the final model. The black paper worked best. Over this the team positioned the trolley with its cantilevered arm that could move across and incrementally shoot the entire area, photo by photo. The camera height could be adjusted using a slider and the camera angle could be adjusted using a ball head.

Here is my project note from the morning of the second day:

“Light tests and light adjustments are done. We add a Speedlite to the mix of lights to deal with a corner that was a bit dark. We will trigger the Speedlite (Michael’s Canon 600) with the PocketWizard TT1 and TT5 combo and all 4 Monoblocks are set to slave mode. It takes a bit of time to tune everything in using the light meter and small adjustments. We feel now the entire sail is evenly lit and imaging can begin.”

Scale bars were placed around the small end of the sail as were color checkers. Using a Canon 5DSR with 24mm f2.8 IS USM lens, and shooting at 18 inches distance from the subject, the imaging began with a calibration pass with 90-landscape-270 rows – then returned to the 90 position for the remainder of the imaging in that pass.

The feathers that trim the sail presented a significant imaging challenge: they stick up, and there are knots and places where the material juts out. The camera focus was set manually to allow some extra depth of field above where the main body of the sail was laid out, so that these elements would remain in focus.

As the work progressed, I recorded this:

“We completed the second pass of the sail with a 50mm lens today and shot 3 RTIs of detail areas chosen by Donna from the Maori textile team. Then we had a crew come in to turn the sail over, and we prepped everything for the back side (which is actually more important for the weavers). We will begin shooting that first thing tomorrow.”

Image: © TeRa Project, Marsden Fund, 2020:

After completing the work on site each day, we returned to our London apartment and began the next step: processing the images of the sail. We have built the RTIs and some other high-resolution 2D outputs of the sail and shared them with the team. The detail is fantastic. We look forward to the team’s continued research and the publishing of their findings, along with our imaging results.

Special thanks to: Donna Campbell, co-Principle Investigator (co-PI) for the research project worked closely with us on site; Julie Adams, Curator of the Oceania Collections at the British Museum, hosted the imaging project; Michael O’Neill, a photographer from the National Museum of New Zealand Te Papa Tongarewa; Kira Zumkley, a London-based heritage photographer and researcher; and Jill Hassell, museum assistant. Catherine Smith, co-PI on the project aided in logistics and overall project management.

You can read more about the sail in the research team’s blog and also the British Museum’s description of the sail from its online collection.

Filed under: Equipment, Guest Blogger, Lighting, Technology | Tags: capture, guest blogger, paste print, Reflectance transformation imaging (RTI), RTIViewer, specular enhancement

Our guest blogger is Dr. Lothar Schmitt, a post-doc in the Digital Humanities Lab at University of Basel in Switzerland. Thank you, Lothar!

For some people early prints are a boring topic, but a few specialists appreciate these crude woodcuts and engravings with their stiffly rendered religious subjects. There are reasons for this unusual predilection: Beginning in about 1400, prints became an increasingly important means to make images affordable for the general public. In addition, printing images stimulated the development of several technical innovations. Among these are ways to reproduce three-dimensional surfaces and to imitate the appearance of precious materials like gold reliefs or brocade textiles.

One such technique is called “paste print.”

With only about 200 examples existing worldwide, this kind of print is rare. It consists of a layer of a slowly hardening oil-based material (Fig. 1, No. 3) that was covered with a tin foil and brushed with a yellowish glaze in order to look like leaf gold (Fig. 1, No. 4). All these layers were stuck to a sheet of paper (Fig. 1, No. 1). To produce an image, the surface of an engraved metal plate was coated with printing ink and pressed into the paste. Through this process, the printing ink was transferred as a dark background (Fig. 1, No. 5), while the cut image of the metal plate generated a relief of golden contours and hatchings. Since these layers became brittle over time, most paste prints are heavily damaged (Fig. 1, No. 2). Moreover, the subjects they show are sometimes hard to decipher.

Traditional photographs are not well suited to reproduce paste prints because it is impossible to record the interaction between the light and the barely discernible relief of the print’s surface with one single capture. To document such effects, our team, a Swiss National Science Foundation (SNSF) research group of four people at the Digital Humanities Lab in Basel, Switzerland, made the decision to try Reflectance Transformation Imaging (RTI). The benefits of RTI are ideal for revealing the material properties of the prints. However, since RTI is not able to properly reproduce the gloss of a metal surface, we were unsure about the results. The first test was very promising.

We traveled from Basel to nearby Zürich, where there is a paste print of an unidentified saint glued into a manuscript at the Zentralbibliothek Zürich (B 245, fol. 6r). The library staff, among them Rainer Walter and Henrik Rörig, were very helpful. Peter Moerkerk, head of the digitization center, even made a high-resolution scan of this print that we could use as a reference image (Fig. 2).

Fig. 2: High-resolution scan of a paste print of an unidentified saint from manuscript B 245 in the Zentralbibliothek Zürich.

For capturing RTIs we constructed a Styrofoam hemisphere with a diameter of 80 cm. On the inside of the hemisphere, there are 58 evenly distributed LEDs that can be triggered in succession. The LEDs are synchronized via a simple control unit that is connected with the flash sync port of the camera. The control unit coordinates with the interval mode of the camera in order to capture a sequence of images automatically. The resulting RTI file shows the subtle surface texture and is instrumental for comprehending the relief and the layered structure of the print (Fig. 3).

As we pointed out earlier, the glossy effects of the golden parts appear too dull, but the “specular enhancement” feature of the RTIViewer helps to distinguish between the surface conditions of the different materials that were employed to make the print.

RTIs of two other paste prints in Switzerland and several others in German collections will be captured in 2015 and 2016. If you are interested in our proceedings, please see our web site: http://dhlab.unibas.ch/?research/digital-materiality.html

Filed under: Commentary, Guest Blogger, Lighting, On Location, Technology | Tags: capture, guest blogger, medieval, mosaic, Preservation, PTM, Reflectance transformation imaging (RTI), tesserae

Our guest blogger is Heidrun Feldmann, a PhD student in History of Art at the University of Basel and an assistant on the research project “Digital Materiality” at the Digital Humanities Lab there. Thank you, Heidrun!

It is obvious that art historians need good reproductions of works of art to do their research. However, photographic images, which are static and two-dimensional, are not capable of reproducing the visual impression we have when we look at mosaics. Their specific materiality and surface properties make a visualization of these characteristics difficult. Besides, as ancient or medieval mosaics are usually placed on the walls of churches, they interact with those specific surroundings. The lighting conditions inside these buildings, as well as the optical impressions for a visitor moving across the room, change dynamically, which results in a unique sensory experience. This is also a reason why the designs of mosaics in such religious contexts were often attuned to the liturgy. The impressive sparkling effect is caused by the surface properties of the countless tesserae, which – when animated by light − shimmer in many different colours and shine like precious metals. Sometimes those tesserae were placed in the setting bed with a certain tilt angle. This might seem irregular to us today, but then it was done intentionally to optimize the reflectivity of the surface.

With the aid of RTI (Reflectance Transformation Imaging), we now have more options for capturing and simulating the reflection properties of a mosaic’s surface, as well as its interaction with changing light conditions. The RTIViewer software enables us to convey the impressions of this highly dynamic medium to people who cannot visit the actual mosaic in situ. RTIs also help us document the current condition of mosaics more accurately than in the past, and they support our goal to answer questions about how light was used in medieval architecture.

To test the RTI method, we visited the Bode-Museum in Berlin, where a mosaic, originating from the church of San Michele in Africisco, Ravenna, is exhibited as part of the Early Christian and Byzantine Collection (Figure 1). We thank Gabriele Mietke, curator of the department, for allowing us to take our photos. The mosaic is fitted into the architecture of the museum, where an apse was constructed to imitate the original place of its installation in the church in Ravenna, albeit without the original lighting situation.

Figure 1: The team of the Digital Humanities Lab taking photographs of the mosaic at the Bode-Museum, Berlin.

Scholars have extensively debated the condition and state of preservation of this mosaic. Without going into all the details, we can say it is certain that the mosaic we see in the museum differs from the original of 545 AD because of its turbulent history. It has been restored and changed more than once, and some critics say that the whole mosaic is merely a copy. For us this was particularly interesting. We were wondering if the RTIs would provide further information regarding interventions, changes, or repairs.

Because of its size and form, it was impossible to take pictures that cover the whole of the apse. Therefore we captured it in twelve segments. About sixty photographs were taken of each of these segments, changing the position of the flashlight by hand for every picture. The twelve RTI files we obtained in this way show the reflection properties much better than any static photograph could do.

There are some limitations with glossy surfaces, because specular reflection cannot be adequately represented with the typical mathematical model used in Polynomial Texture Maps (the first form of RTI). However, changing the angle of the incoming light in the RTIViewer software allows us to identify areas whose structure and reflection properties differ from the others. In those areas the tesserae are of a different size or form and seem to be set in another way. All this suggests that these are the areas where the mosaic has undergone some kind of repair or restoration (Figures 2 and 3).

Having successfully tested the technique under the special conditions in the museum, we are now looking forward to the next step: capturing RTIs of medieval mosaics in situ and working on enhanced models for the visualization of gloss.

To find out more about our research project, see http://www.dhlab.unibas.ch.

By Marlin Lum

640ws Einstein monolight – by Paul C Buff

Word on the street. We’ve got the good pleasure of knowing, (that some time soon), Paul C. Buff, (manufacturer of our fondly desirable Alien Bee Lighting strobes) will be shipping the Einstein monoblocs.

Many of you might be using the Aliens Bees to as your light source for HighLight RTI captures. If you’re in the market for a monobloc, you might want to look into this unit. Though not yet available, this unit would take you to the next level, improving upon the alien bee line.

The new 640ws monolight seems pretty top shelf. Got features? Good stuff mate.

Just a few highlights:

–Worldwide power compatibility (95-265VAC, 50Hz or 60Hz, autoswitching)

-Full power recycle time of 1.7 seconds at 120VAC (60Hz) or at 240VAC (50Hz)

–CONSTANT COLOR and ACTION modes; one is optimized for colour temperature consistency and the other for stopping motion (uhm, sweeeet, but never throw away your gray card)

–Removable Pyrex flash dome over the flash tube and modeling light (got to love that)

-roughly the same size as the AB 1600, but heavier, bc it’s got some steel in it.

–Illuminated LCD display and push button controls for setting and reviewing of flash functions (don’t get left in the dark)

-The formal official name of this product = “Paul C. Buff Einstein 640”

Release Date

The Einstein 640 release date is (tentative) but due in December 2009 direct from Paul C. Buff at an aprox price of about US$439.00.

Geek Out and read more at the Rob Galbraith site.